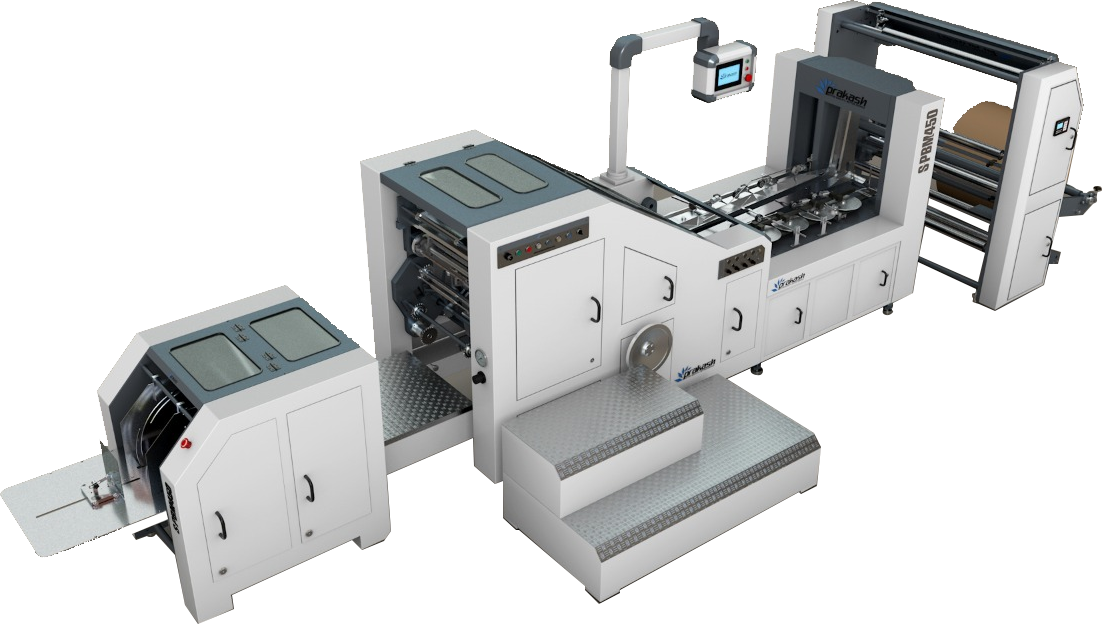

Square Bottom Paper Bag Making Machine (SPBM 450)

Roll Feeding Square Bottom Paper Bag Making Machine

Download Brochure Download Brochure Watch Video Watch Video

Roll Feeding Square Bottom Paper Bag Making Machine

Square bottom paper bag making machine has got lot of applications. It can be used to produce shopping bags, grocery bags, food bags, paper bags with handles and stylish bags used for gifts. This special machine produces the paper bag in one process from printed or unprinted roll paper, side gluing, roll folding, roll paper cutting, bottom folding, bottom gluing forming, bag formation in one go. Machine is controlled by PC programmable servo motor through the human-machine touch screen interface. It can produce variety of specifications' paper bags. It has various advantages such as high production, quick changeover, operator friendly and fully automatic.

Features

-

Small footprints and compact designs

The compact design of the machine, ensures that the paper travels smoothly. This helps in producing better quality paper bags and with better finishing.

-

Simplistic Tube Forming System

Prakash paper bag machine comes with simple system to adjust tube formation. This greatly helps in varying paper bag sizes and operator freindliness.

-

Fully Automatic Glue Supply System

Automatic glue supply system is adopted for coating at the bottom. If the amount of glue in the glue tank is insufficient, the glue will be supplied automatically to avoid glue.

-

Automatic Counting System

The machine has automatic counting system. Not only it counts the total bags produced but operator can preset small batch size. As soon as small batch size is reached

-

Touchscreen and PLC

Prakash machine uses highly adaptive touch screen and PC control system. This user friendly GUI shows real time data to the operator, enhancing ease of work.

-

Color Mark Tracking System

Precise cut to print is achieved by highly accurate print mark sensor. Machine software easily reads print mark on the paper and cuts the paper bag length as per the mark.

Specification Details

Size

Size

9400 x 2200 x 1925

MM

weight

weight

9000

KG

Material

Material

Steel &

Fiber

Warranty

Warranty

1

Year

Capacity

Capacity

180 Pcs

/ Min

| SPECIFICATIONS | SPBM-200 | SPBM-360 | SPBM-450 |

|---|---|---|---|

| Bag Width (W) | 80-200 MM | 135-360 MM | 230-450 MM |

| Bottom Size (H) | 50-105 MM | 80-200 MM | 80-200 MM |

| Bag Tube Length (C) | 190-370 MM | 270-530 MM | 270-530 MM |

| Bag Length (L) | L = C- (11+2+15-25) | L = C- (H+2+15-25) | L = C- (11+2+15-25) |

| Max. Speed | 260 Pcs/Min | 200 Pcs/Min | 180 Pcs/Min |

| Paper Thickness* | 45 -130 GSM | 48 -150 GSM | 60 -160 GSM |

| Paper Roll Width | 280-630 MM | 485-1110 MM | 645-1250 MM |

| Max. Roll Diameter | 1200 MM | 1200 MM | 1200 MM |

| Reel Inner Diameter | 76 MM | 76 MM | 76 MM |

| Total Power | 7.5 KW | 11 KIN | 11 KW |

| Roll Shaft | Air Shaft | Air Shaft | Air Shaft |

| Roll Lifting System | Hydraulic | Hydraulic | Hydraulic |

| Tension Control System | Close Loop Pneumatic Brake With Load Cell Feedback | ||

| Weight of Machine | 6000 KG | 8500 KG | 9000 KG |

| Overall Dimension (L x W x H) | 6600 X 1400 X 1500 MM | 9400 x 1900 x 1925 MM | 9400 x 2200 x 1925 MM |

- Easy to use and operator friendly machine, helps in giving high production and maintenance free.

- Fully automatic with plc control gives full control over the machine.

- Small footprint enables easy stallation and less space requirement.

- Automatic lubrication system, increases machine life considerably.

- Pneumatic reel lifting helps in quick changeover and less labor.

- Auto tension control system keeps bag quality and finishing as per the international standards.

- Automatic counting system helps in easy collection of finished paper bags and simpler production planning.

Contact Form

Got a question? We'd love to hear from you. Send us a message and we'll respond as soon as possible

Subscribe to our newsletter

Join our newsletter list to get the latest news, update and special offers directly in your inbox.

.png)