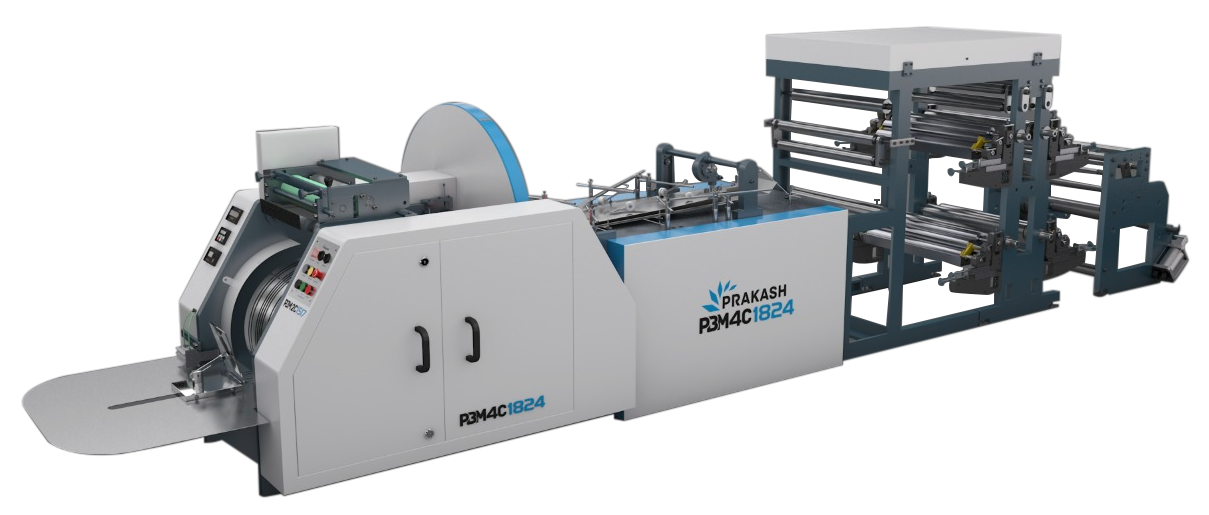

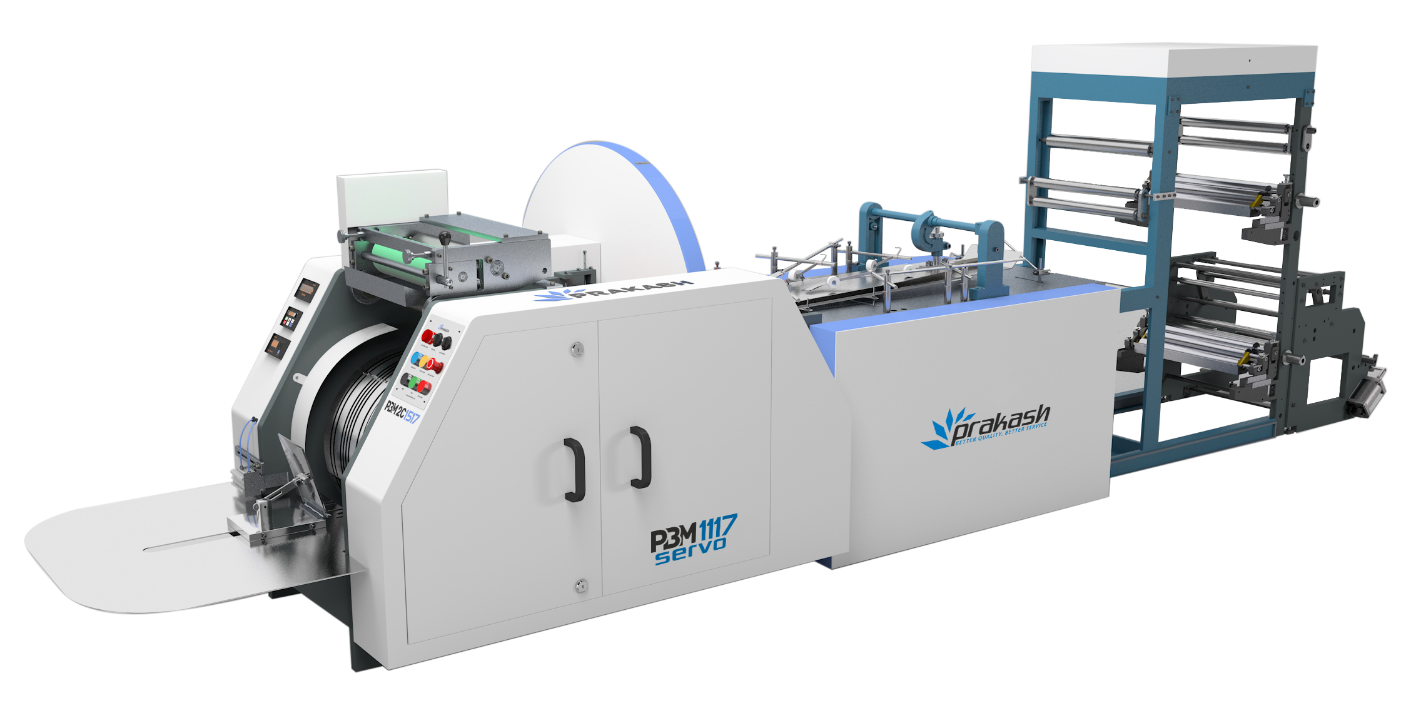

V Bottom Paper Bag Making Machine (PBM4C 1824)

Roll Feeding V Bottom Bag Making Machine

Download Brochure Download Brochure Watch Video Watch Video

Cutting and Bag Collection Section

- Super fine high carbon, high chromium cutting knife for long life and smooth cutting.

- 4 nos. flying knife for high speed and high production.

- Counter system for total bag count and batch counter.

- Dynamically balanced, high grade alloy steelmain collection drum for vibration & maintenance free operations.

- 2 minute change gear mechanism for bag length change.

- Kicker system for bag bundle batching.

Reel Stand

Prakash offers a sturdy and a dedicated reel stand for paper reels. Made with steel, reel stand orders several advantages. Reel stand is built such a way that it can serve both purposes of center passing or side pasting. It is built with solid steel, which means it is rugged and heavy duty giving a long life.

Watch Video Watch VideoRoll Feeding V Bottom Bag Making Machine

Prakash Grocery paper bag making machine is a revolutionary machine, which is mastered to produce finest quality paper bags with or without side gusset. With V-cut at the bottom of the paper bag, it is the most economical type of paper bag that can be produced. These paper bags can be produced in different sizes and have got wide usage in groceries, packing, confectionary, food stuff, tea powder, medical field. Paper bag size can be easily changed by changing the gear, which controls the length of the bag precisely. Change in size is very easy and can be done in no time. Machine performance is high because of its rugged structure and high quality components. All its components are made on highly precise CNC machines and correct metallurgy of the components ensures long life of the machine.

Download Brochure Download Brochure

Specification Details

Size

Size

4500x1600x1600

MM

weight

weight

3000

KG

Material

Material

Steel &

Fiber

Warranty

Warranty

1

Year

Capacity

Capacity

400 Pcs

/ Min

| SPECIFICATIONS | PBM2C-1117(11″) | PBM2C-1517(15″) | PBM2C-1824(18″) |

|---|---|---|---|

| Cutting Length | 150-460mm | 150-460mm | 185-605mm |

| Bag Length | 140-455mm | 140-455mm | 180-600mm |

| Bag Width | 100-280mm | 100-380mm | 100-450mm |

| Gusset Depth | 0-100mm | 0-125mm | 0-175mm |

| Standard Flap | 12-20mm | 12-20mm | 12-20mm |

| Max Speed* | 400 Pcs./Min | 400 Pcs./Min | 400 Pcs./Min |

| Paper Thickness | 30-80gsm | 30-80gsm | 30-120gsm |

| Paper Roll Width | 220-780mm | 220-980mm | 220-1270mm |

| Max. Roll Diameter | 1000mm | 1000mm | 1000mm |

| Total Power | 3Kw | 3.5Kw | 5Kw |

| Plate Thickness | 2.84mm | 2.84mm | 2.84mm |

| Overall Dimension | 4500x1600x1600mm | 5000x1850x1600mm | 5000x2440x1700mm |

| Weight of Machine | 2500Kgs | 3000Kgs | 4800Kgs |

- Laser cut size plate for precision and smooth tube formation.

- Size plate mounting bracket comes with liner and cross setting options.

- Chrome plated size plate for long life and corrosion.

- Side pasting available as an option & On the run gusset size adjustment.

- Size plate provided as a complete set with top and bottom plate, cutting knife and glue strip for really quick bag size changeover resistance.

Contact Form

Got a question? We'd love to hear from you. Send us a message and we'll respond as soon as possible

Subscribe to our newsletter

Join our newsletter list to get the latest news, update and special offers directly in your inbox.