Welcome to Prakash Group of Industries - India's Largest Manufacturer of Paper Bag Making Machines.

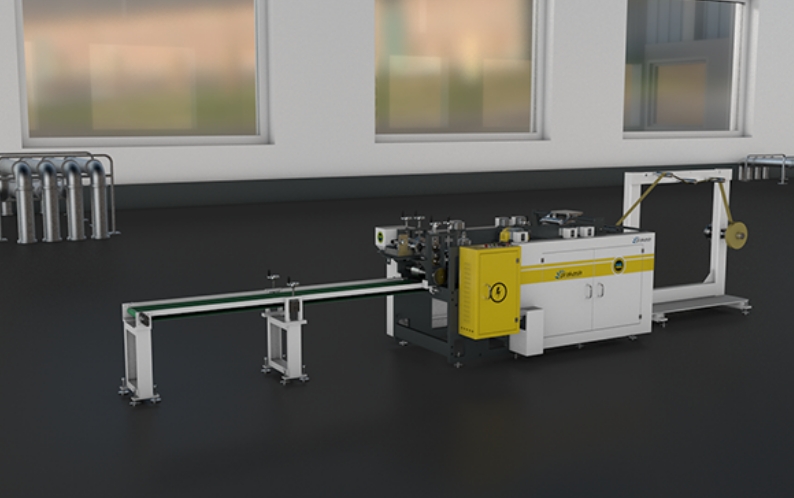

Easy to use and operator friendly machine, helps in giving high production and maintenance free.

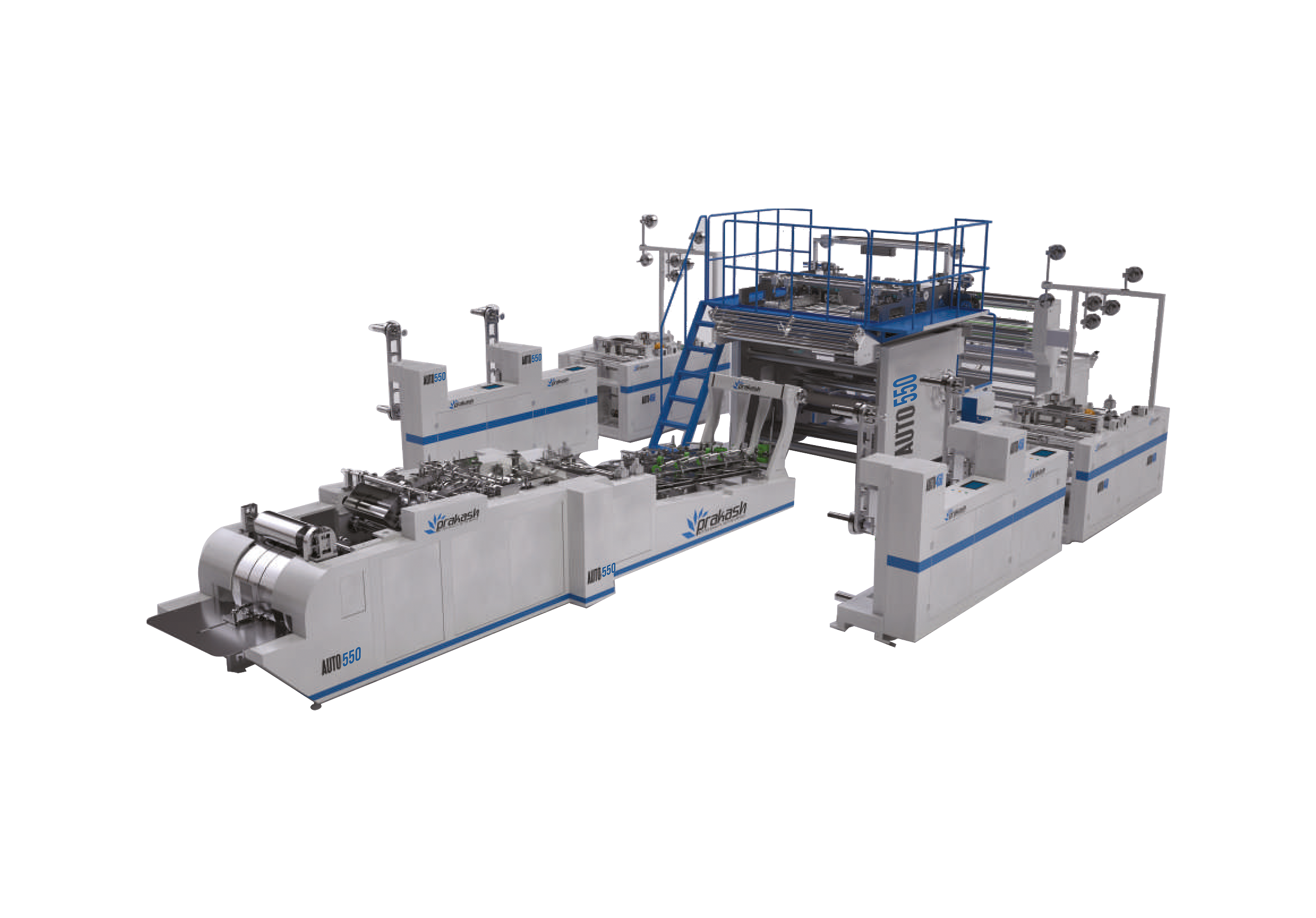

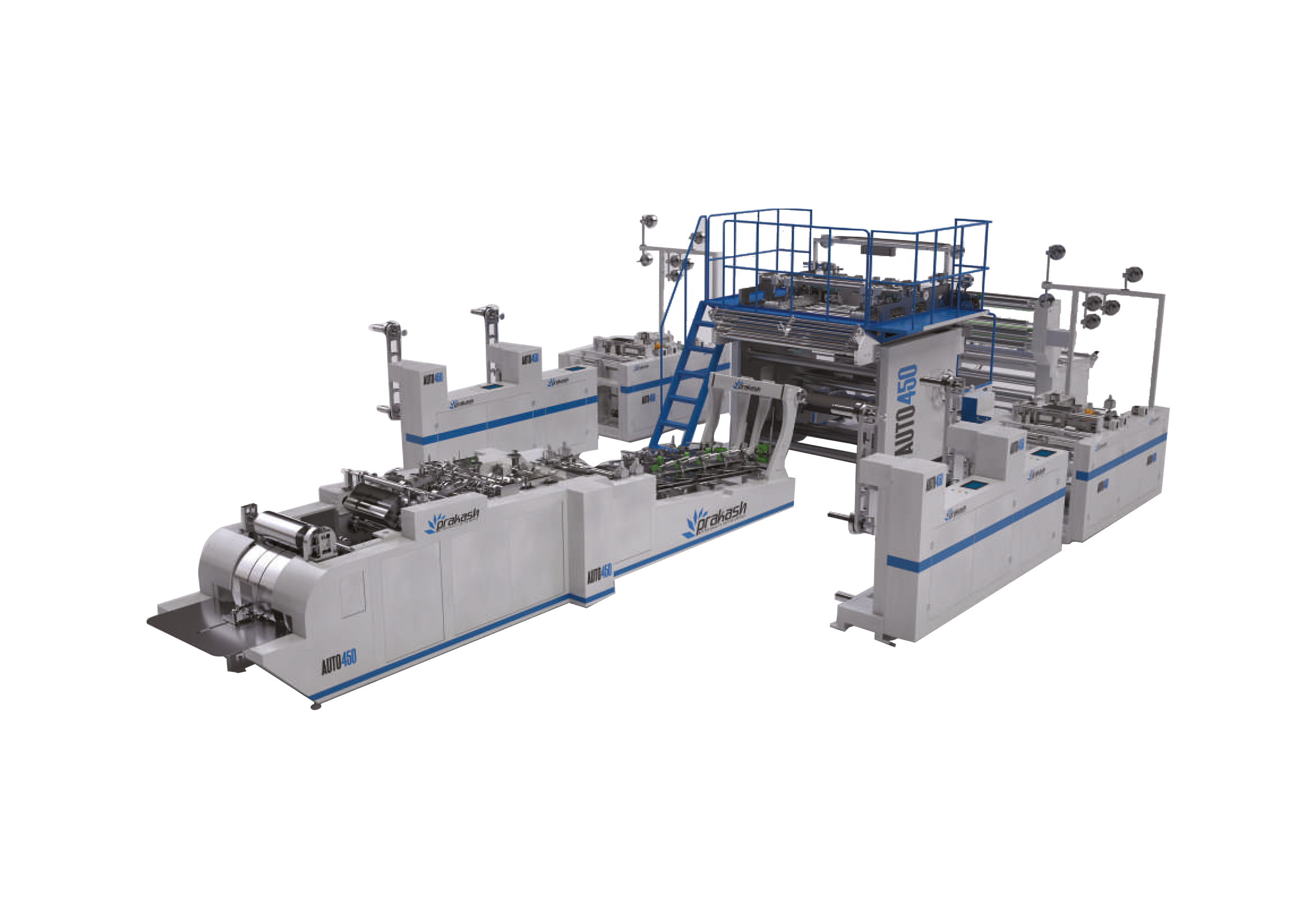

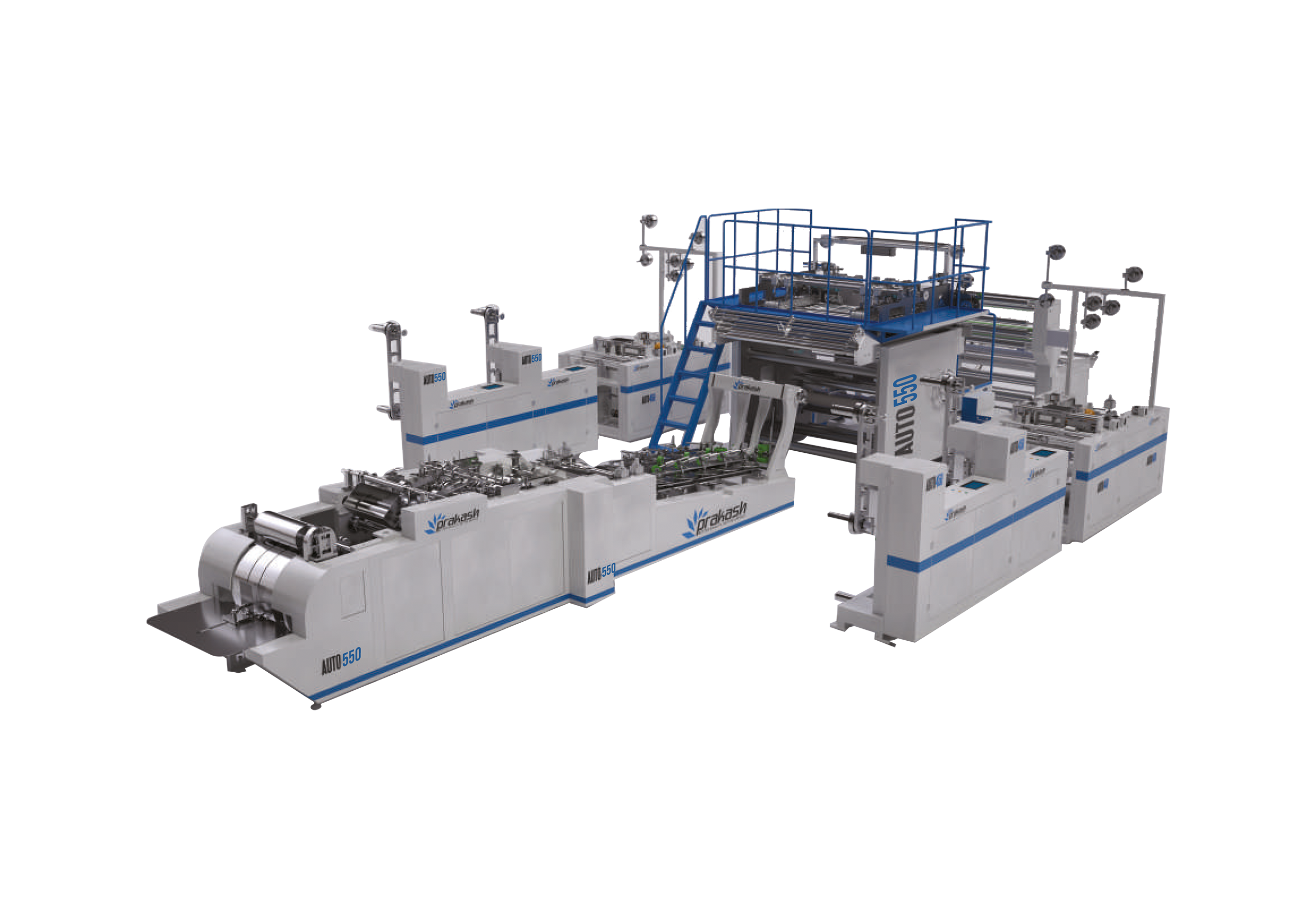

Fully automatic with plc control gives full control over the machine. Automatic lubrication system, increases machine life considerably

Fully automatic with plc control gives full control over the machine. Automatic lubrication system, increases machine life considerably

Fully automatic with plc control gives full control over the machine. Automatic lubrication system, increases machine life considerably

Find out why people love working with Prakash Offset

We work closely with Prakash Offset, we were the first one to trust their Newslight line of machine and placed orders for several 24 pages, all pages colour Newslight presslines. We are happy with the product and its performance. Prakash's inclination towards innovation and technology is admirable. I wish them all the best and good luck for the future.

AVP- Production

Prakash Web Offset has been associated with jagran Prakashan for several years. We are using Prakash presses, Load bearing Autopaster SG 50 at our printing centres. We have good experience with them.

Senior General Manager

I am really happy to see prakash Web Offset focus on technology and new products. We are using several of its product lines such as Newslight 36, SG 50, and Speedster. Prakash is doing a good job in maintaining quality and service levels. Hope you will continue your good work.

Chief Technical Officer

We are a long standing customer of Prakash Press and are using several 24 pages all pages colour machine from Prakash. We are satisfied with their quality and service. I wish them all the best for the future.

General Manager (Operations)

We are using Prakash machines at our several locations not just towers but also turner bars, autopaster, and web cleaner. I can confidently say that Prakash has proven that it is a strong player in the industry by offering innovative products and by maintaining good quality standards. Stay focussed, god bless!

VP- Production

Easy to use and operator friendly machine, helps in giving high production and maintenance free

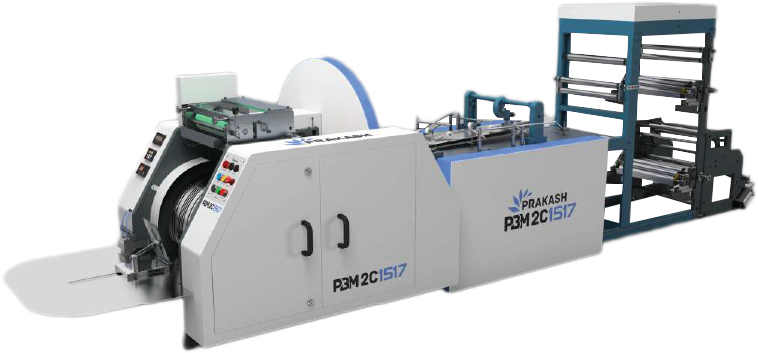

This special machine produces the paper bag in one process from printed or unprinted roll paper, side...

Read More

Precise cut to print is achieved by highly accurate print mark sensor. Machine software easily reads...

Read More

Prakash paper bag machine comes with simple system to adjust tube formation. This greatly helps in varying...

Read MoreFlexographic Printing Machine has got full flexibility and high production and quality features.

In the FLV Series, individual color stations (sometimes called sections or decks) are stacked one over the both sides of a main press frame. Each color station is driven through gear trains supported bythe main press frame.

We at Prakash Offset undertake extreme pride in endorsing our expertise and widely appreciated mastery over manufacturing...

4 COLOUR PRINTING MACHINE is aptly designed keeping mind high production requirements...

At Prakash, we are offering the premium quality Printing Machine to our esteemed patrons manufactured precisely to...

These are satellite models built in 3-in-1 Model Machine pattern suitable to print two cut colours in single pass on the following...

With V-cut at the bottom of the paper bag, it is the most economical type of paper bag that can be produced.

Machine is equipped with pneumatic reel lifting to ease the operation and better roll handling.

Read More

Machine is fully automatic and runs at high speed of 400 bags per minute with 4 rotating blades.

Read More

Automatic tension control system is provided with pneumatic disc brake at unwind unit.

Read MoreThis machine mainly supports semi automatic paper bag machines.

PRAKASH RHM-1000 twisted rope handle making machine is a high-speed paper handle making machine.

This machine mainly supports semi automatic paper bag machines. It can quickly produce paper handles

Twisted paper ropes are widely used to make handles for shopping bags. It’s a high speed and high production twisted

The machine uses narrow web as raw material, through the high speed spinning of the axes of the machine.

This machine is mainly supporting twisted paper rope machine. It is applicable to rewind the target paper rope roll

Web offset presses and Web offset machines are used to print on both sides of roll (web).